atv repair manual

An ATV repair manual is essential for effective maintenance‚ troubleshooting‚ and repairs. It offers detailed guidance for both novice and experienced users‚ ensuring safety and cost-effectiveness always.

1.1 Importance of a Comprehensive Guide

A comprehensive ATV repair manual is crucial for ensuring proper maintenance‚ troubleshooting‚ and repairs. It provides detailed instructions‚ diagrams‚ and specifications tailored to your ATV model. With a reliable guide‚ you can diagnose issues accurately‚ such as engine misfires or electrical faults‚ and perform fixes confidently. Regular maintenance steps‚ like oil changes and spark plug replacements‚ are clearly outlined to prevent future problems. A good manual also covers essential safety precautions‚ reducing risks during repairs. Whether you’re a novice or an experienced owner‚ a comprehensive guide empowers you to keep your ATV in optimal condition‚ saving time and money in the long run.

1.2 Benefits of DIY Repairs for ATV Owners

DIY repairs empower ATV owners to save money‚ gain mechanical knowledge‚ and customize their vehicles. By following a repair manual‚ owners can address issues promptly‚ reducing downtime and extending the ATV’s lifespan. DIY also fosters a deeper understanding of the machine‚ enabling better maintenance and troubleshooting; Additionally‚ it allows for personalized upgrades and modifications‚ enhancing performance and functionality. While it requires time and effort‚ the long-term benefits of DIY repairs far outweigh the costs‚ making it a valuable skill for any ATV enthusiast.

Essential Tools and Equipment for ATV Repair

Must-have tools include wrenches‚ screwdrivers‚ pliers‚ and a multimeter. Specialized equipment like a torque wrench and hydraulic press may be needed for advanced repairs‚ ensuring safety and efficiency always.

2.1 Must-Have Tools for Basic Maintenance

For basic ATV maintenance‚ essential tools include a socket set‚ wrenches‚ screwdrivers‚ and pliers. A multimeter is crucial for diagnosing electrical issues. A tire pressure gauge ensures proper tire inflation‚ while a spark plug socket facilitates easy replacement. Pliers and punches are handy for adjusting chains and cables. An air compressor can help clean components and inflate tires. A funnel and drain pan are necessary for oil changes. Lastly‚ a torque wrench ensures bolts are tightened correctly‚ preventing damage. These tools form the foundation of any ATV repair toolkit‚ enabling owners to perform routine tasks safely and efficiently‚ while adhering to manufacturer guidelines.

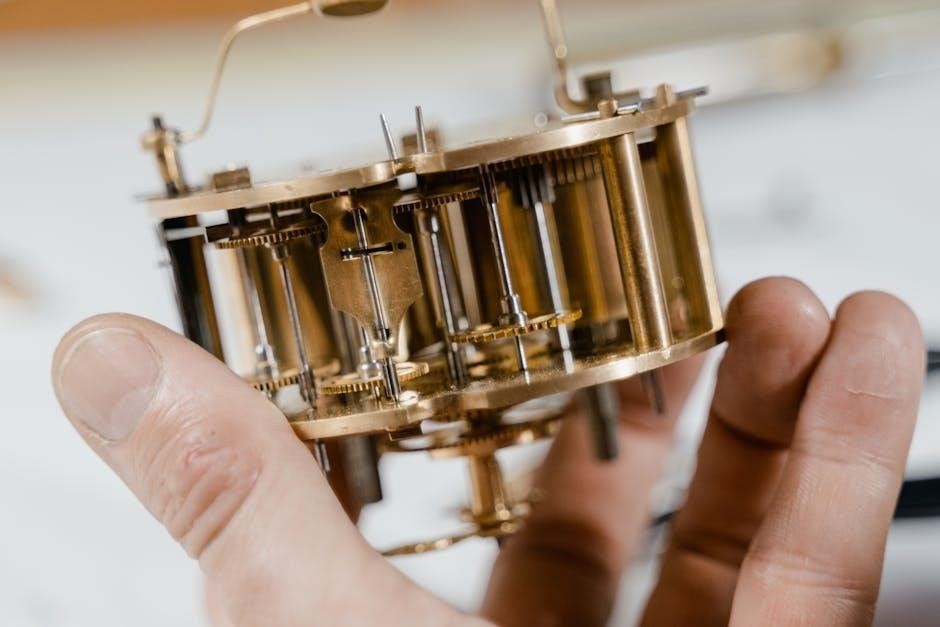

2.2 Specialized Tools for Advanced Repairs

Advanced ATV repairs require specialized tools‚ such as a piston ring compressor for engine overhauls and a crankshaft puller for replacing bearings. A hydraulic press is essential for pressing bearings and bushings. For transmission work‚ a gear puller and bearing extractor are indispensable. Additionally‚ a dial indicator helps measure crankshaft and camshaft alignment. A set of precision gauges ensures accurate clearance measurements. These tools enable complex repairs‚ such as rebuilding engines or overhauling transmissions‚ ensuring precision and safety. While they may be costly‚ they are vital for tackling advanced mechanical issues effectively and efficiently‚ especially for experienced ATV enthusiasts or professionals.

Troubleshooting Common ATV Issues

Troubleshooting ATV problems often starts with identifying symptoms like misfires or starting issues. Check spark plugs‚ fuel systems‚ and electrical connections to diagnose root causes effectively always.

3.1 Diagnosing Engine Problems

Diagnosing engine issues in ATVs involves checking for common symptoms like rough idling‚ misfires‚ or lack of power. Start by inspecting spark plugs for wear or fouling‚ ensuring proper connections. Check the air filter for dirt or blockages‚ as a dirty filter can restrict airflow. Fuel system issues‚ such as clogged jets or faulty fuel injectors‚ often cause poor performance. Use a multimeter to test electrical components like ignition coils or sensors for any malfunction. Regular oil analysis can reveal internal engine wear‚ helping to address problems before they escalate. Always refer to the repair manual for specific diagnostic steps tailored to your ATV model.

3.2 Identifying and Fixing Electrical System Faults

Diagnosing electrical issues in ATVs requires a systematic approach. Start by checking the battery for charge and connections‚ as a dead or loose battery can mimic other faults. Test spark plugs and ignition coils for proper function‚ as faulty components often cause misfires. Inspect wiring harnesses for damage or corrosion‚ ensuring all connections are secure. Use a multimeter to verify voltage at critical points‚ such as sensors and relays. If issues persist‚ consult the repair manual for specific troubleshooting steps tailored to your ATV model. Addressing electrical faults promptly prevents further damage and ensures reliable performance.

Step-by-Step Repair Guides

This section provides detailed‚ step-by-step instructions for common ATV repairs. From carburetor replacement to transmission and suspension fixes‚ these guides ensure precise and efficient DIY solutions always.

4.1 Replacing the Carburetor and Adjusting Settings

Replacing the carburetor involves removing the old unit‚ installing the new one‚ and reconnecting fuel lines and cables. Adjust settings by tweaking the air-fuel mixture screws for optimal performance. Ensure proper synchronization to avoid engine issues. Always refer to the manual for specific torque specs and adjustment procedures. After installation‚ test the ATV at varying RPMs to confirm smooth operation. Adjustments may require trial and error‚ so patience is key. A correctly set carburetor improves power delivery and fuel efficiency‚ making the repair worthwhile for ATV enthusiasts seeking peak performance.

4.2 Repairing the Transmission and Gearbox

Repairing the transmission and gearbox requires careful disassembly to identify worn or damaged components. Inspect gears‚ bearings‚ and seals for wear. Replace any faulty parts with OEM or high-quality aftermarket equivalents. Reassemble the unit‚ ensuring all components are properly aligned and secured. Use torque specs from the manual for bolt tightening. After reassembly‚ refill with the recommended transmission fluid and test the ATV under varying conditions to ensure smooth operation. Proper repair ensures reliable power delivery and prevents further damage‚ making it a critical skill for ATV owners seeking longevity and performance from their vehicles.

4.3 Fixing Suspension and Steering Components

Fixing suspension and steering components is crucial for maintaining handling and stability. Inspect shocks‚ struts‚ and steering linkages for wear or damage. Replace worn bushings‚ seals‚ or ball joints as needed. Tighten all bolts to the manufacturer’s torque specifications using a torque wrench. Align the front wheels properly after repairs to ensure straight tracking. Lubricate moving parts to prevent corrosion and friction. Test the ATV on a flat surface to confirm smooth steering and suspension operation. Proper maintenance of these systems enhances safety‚ control‚ and overall riding performance‚ making it essential for both recreational and utility ATV users.

Maintenance Tips to Prevent Future Issues

Regular cleaning‚ inspecting suspension components‚ and checking tire pressure can prevent issues; Store your ATV in a dry place and avoid extreme temperatures to maintain performance and longevity.

5.1 Regular Oil Changes and Filter Replacements

Regular oil changes are crucial for maintaining your ATV’s engine health. Use the recommended oil type and replace filters as specified. This prevents wear‚ reduces emissions‚ and ensures efficiency. Neglecting oil changes can lead to costly repairs. Always refer to your manual for the correct schedule and procedures. Proper disposal of used oil and filters is also important for environmental safety. Consistent maintenance helps extend the lifespan of your ATV and keeps it running smoothly.

5.2 Checking and Replacing Spark Plugs

Regularly inspecting and replacing spark plugs is vital for maintaining your ATV’s performance. Remove the plugs and check for fouling or wear. Clean or replace them as needed‚ ensuring the gap is set correctly. Fouled spark plugs can cause poor engine performance‚ reduced power‚ and decreased fuel efficiency. Always use the correct spark plug type and gap specification for your ATV‚ as outlined in the manual. Proper installation prevents misfires and potential engine damage. Replacing spark plugs is a simple yet critical maintenance task to keep your ATV running smoothly and efficiently. Regular checks help avoid costly repairs down the line.

Safety Precautions During Repairs

Always wear protective gear like gloves and goggles. Ensure the ATV is on a stable stand and the battery is disconnected. Proper ventilation is crucial for safety.

6.1 Proper Use of Safety Gear

Wearing appropriate safety gear is crucial when repairing an ATV. Always use gloves to protect your hands from cuts and abrasions. Safety goggles or glasses are essential to shield your eyes from debris. A face mask can prevent inhalation of dust or harmful fumes. Ensure all gear fits properly and remains secure during repairs. Proper safety gear not only prevents injuries but also enhances focus and precision. Always check your gear for damage before use and replace it if necessary. Prioritizing safety ensures a smoother‚ incident-free repair process. Remember‚ safety gear is your first line of defense against potential hazards.

6.2 Avoiding Common Hazards in ATV Repair

When working on an ATV‚ it’s crucial to avoid common hazards to ensure safety. Electrical systems can be unpredictable‚ so always disconnect the battery before starting repairs. Fuel and coolant leaks pose fire risks‚ requiring immediate attention. Hot engines and exhaust components can cause burns‚ so allow them to cool before handling. Improper use of tools can lead to injuries or further damage. Always follow manufacturer guidelines and use the correct tools for the job. Keep the workspace well-ventilated and avoid over-tightening components. Regularly inspect cables and wires to prevent unexpected malfunctions. Stay alert and avoid rushing repairs to minimize risks and ensure a safe working environment.

Mastering ATV repair requires patience‚ proper tools‚ and adherence to guidelines. For further learning‚ consult official manuals‚ repair forums‚ and certified mechanic resources to enhance your skills effectively.

7.1 Summary of Key Repair Practices

Regular maintenance and prompt repairs are vital for ATV longevity. Always use the correct tools and adhere to the manual’s guidelines to avoid further damage. Start with diagnostics‚ checking for common faults like spark plug issues or clogged air filters. Address electrical system problems by testing connections and fuses. For engine troubles‚ inspect fuel flow and compression. After repairs‚ test the ATV under controlled conditions to ensure functionality. Safety is paramount; wear protective gear and follow proper shutdown procedures. By adhering to these practices‚ ATV owners can maintain performance and reliability‚ minimizing downtime and extending the vehicle’s lifespan effectively.

7.2 Recommended Resources for Further Learning

For deeper knowledge‚ explore manufacturer websites like Yamaha or Honda for model-specific guides; Online forums such as ATVForums.com offer valuable insights and troubleshooting tips. YouTube channels dedicated to ATV repairs provide visual tutorials. Additionally‚ consider enrolling in mechanic courses or workshops for hands-on experience. Official repair manuals and diagnostic tools are indispensable for advanced repairs. Community forums and specialized repair shops can also offer tailored advice. These resources will help you refine your skills and stay updated on the latest ATV maintenance and repair techniques‚ ensuring your vehicle runs optimally for years to come.

Leave a Reply

You must be logged in to post a comment.